Solutions for Surgeons

PDR Research

- Focus:

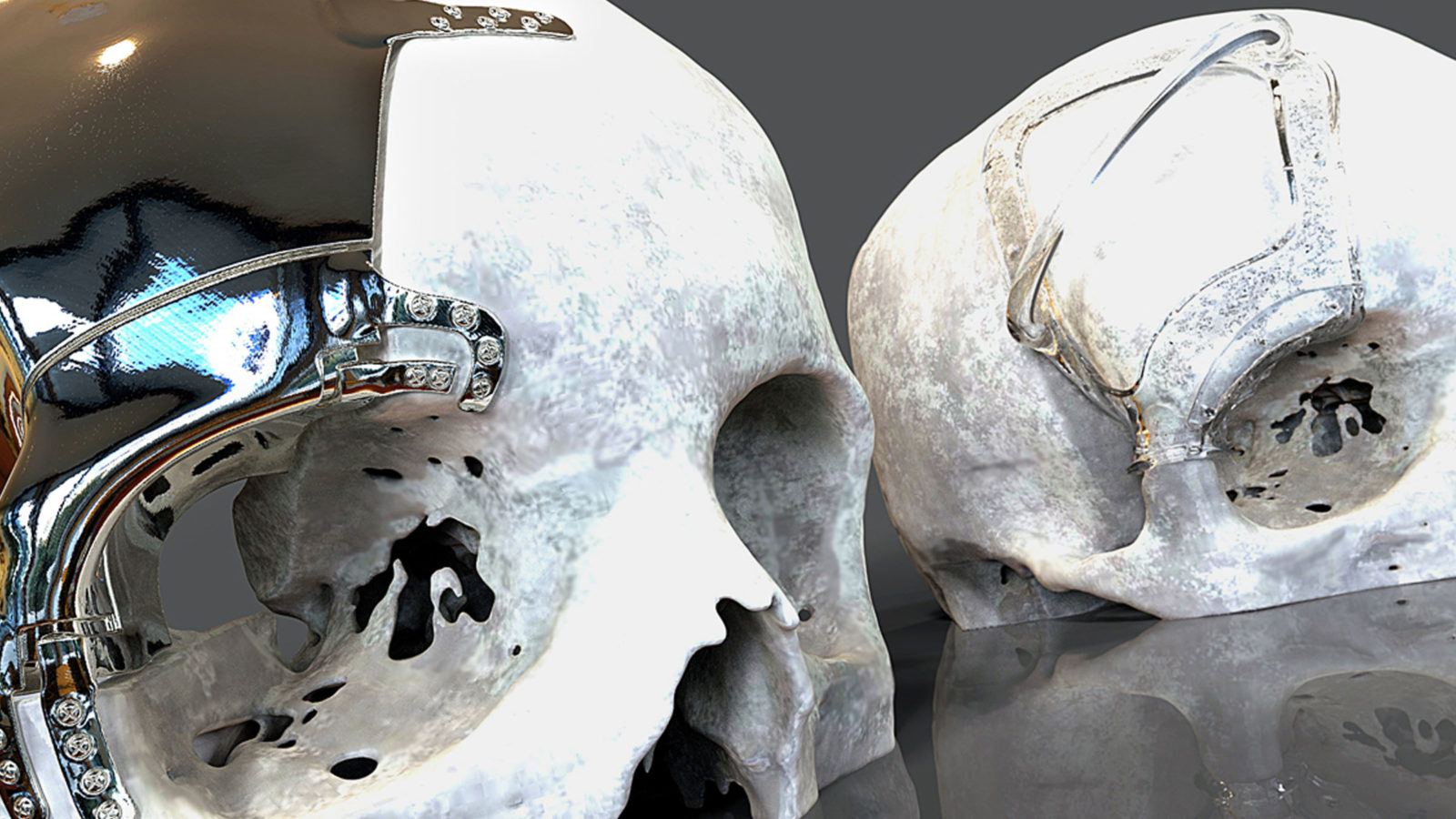

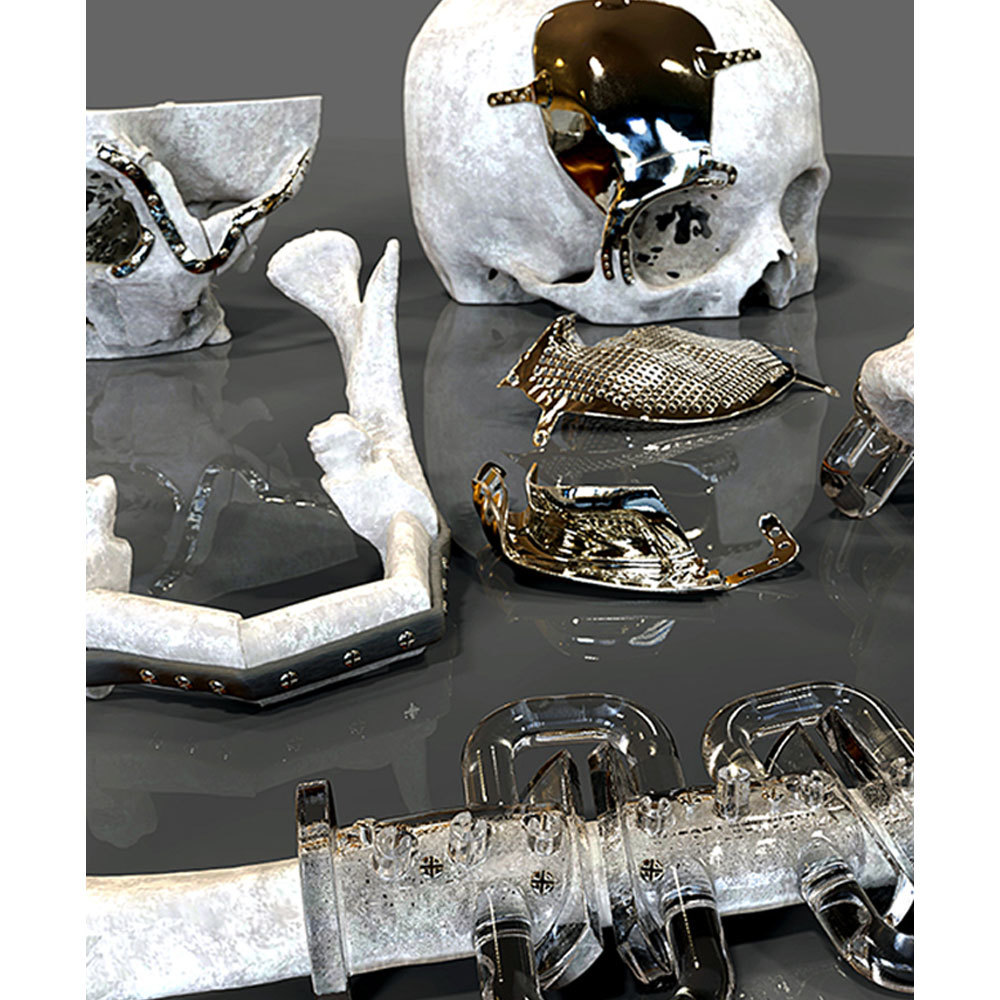

- Surgical Prosthetic Design

COMMON BENEFITS OF 3D PRE-PLANNED SURGERY INCLUDE:

- Reduced dependence on multiple, expensive physical models which are destroyed after one practice

- Reduced risk, especially in complex procedures.

- Creating 3D-printed polymer anatomical models of the outcomes (either by PDR or by your hospital)

- Enabling PDR’s experienced design engineers to realise your designs for custom surgical guides;

- Using those guides to accurately translate digital plans, and reduce operation durations; even when compared to expensive robotic, and navigation-based approaches.

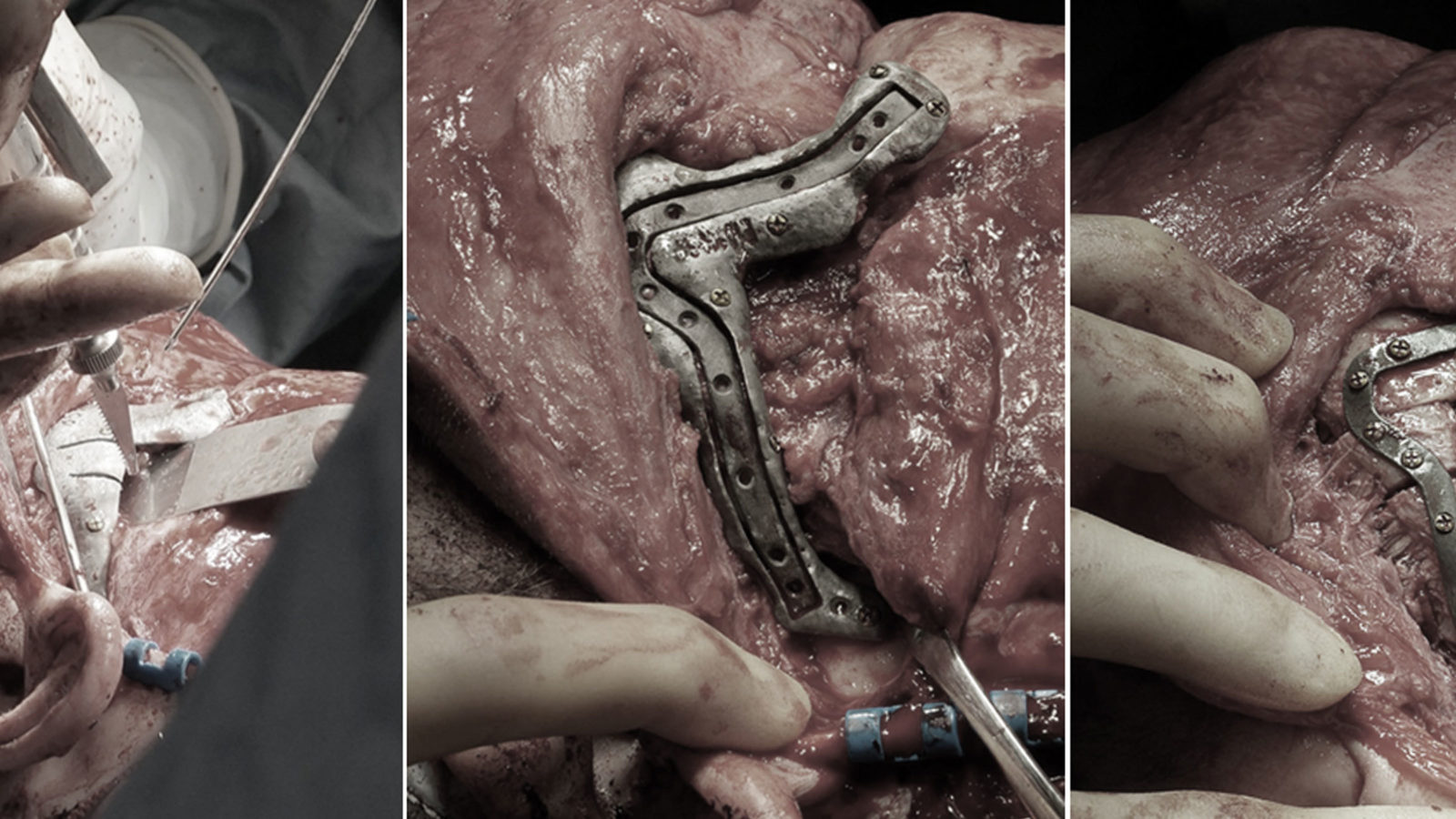

Usually, we will establish your particular requirements during a web-meeting, and enact your plans on virtual models of the anatomy as you watch and direct. This might mean defining the precise margins for disease excision, or verifying the availability and shape of a proposed reconstructive bone graft.

PATIENT-SPECIFIC DEVICES

We will translate your prescription into 3D files of verified designs for patient-specific implants and guides; which are suitable for 3D printing in titanium. By meticulously defining your design requirements, we can model your designs to be effective and safe. Devices must always be made by appropriately qualified manufacturers. We can arrange for verified designs to be manufactured by leading 3D printing experts, Renishaw PLC who are certified to rigorous international medical device quality standards, and who comply fully with medical device regulations.

Our design expertise and our robust procedures are supported by our own peer-reviewed academic investigations, and by regular review of the current state-of-the-art.

PATIENT-SPECIFIC SURGICAL GUIDES CAN BE USED TO CONTROL:

- Drilling locations

- Drilling angles

- Saw cutting vectors

- The repositioning of bones

- The stability of residual bones following resection but prior to grafting

- And the shape of auto-grafts themselves

COMPARED TO ADAPTABLE MASS-PRODUCED STOCK IMPLANTS, 3D PRINTED IMPLANTS HAVE:

- Resulted in better functional outcomes

- Achieved a more accurate fit with better stability

- Resulted in better aesthetic outcomes despite extra surgical constraints

- Reduced theatre time

- Reduced the likelihood of needing surgical revisions

- Decreased stress shielding

- Avoided limb amputations

- Increased the safety of procedures for theatre staff

- Incorporated tailored mechanical properties

- Resolved the most complex and non-standard defects and improved osseointegration, where desired

Additionally, positive secondary effects have been reasonably inferred; such as reduced infection risks and blood loss, and accelerated recovery periods. See our work for representative examples of previous maxillofacial device designs.